Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

Twist Pin Crimping Machine

CORE TECHNOLOGY

Magnetic Damping Wire Reel Loading

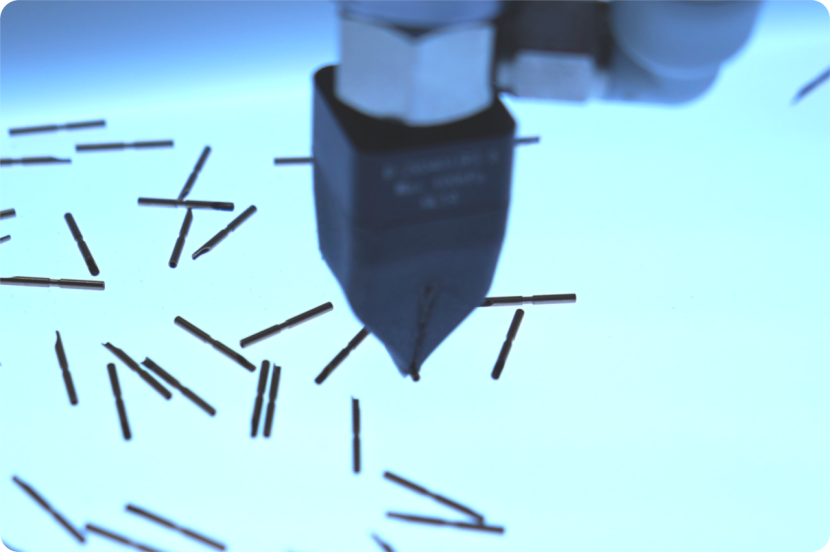

Materials are fed by the flexible vibrating plate. The four-axis robot, in coordination with CCD visual positioning, can accurately grasp them, and it can adapt to the feeding requirements of rear sleeves with different specifications, sizes and shapes.

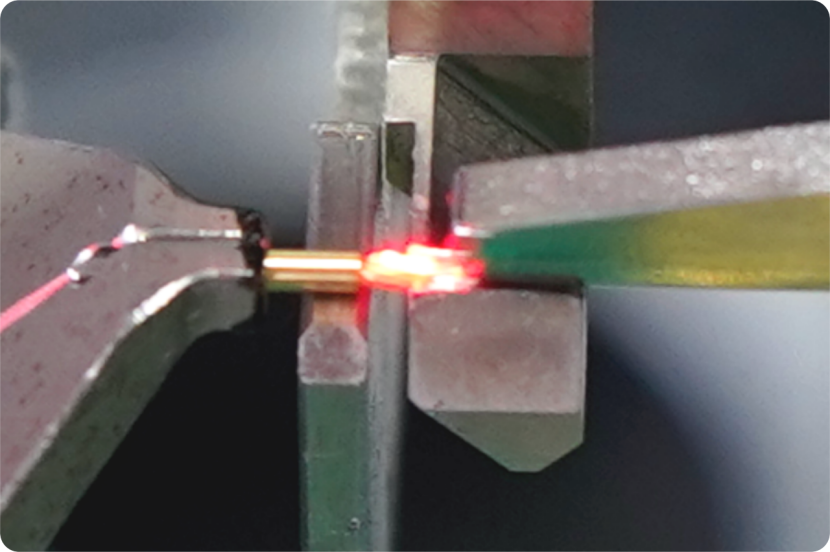

Fiber optic monitoring

Fiber optic monitoring checks for the presence of materials and automatically alarms in case of abnormalities, improving product qualification rates.

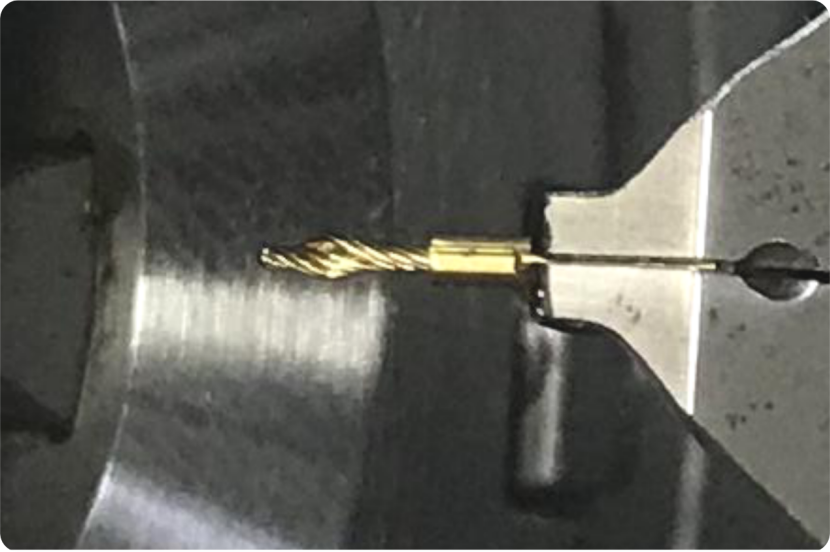

High-precision four-point crimping

High-precision four-point crimping ensures a tight connection between the twist pins and the rear sleeves with high consistency. The fixture can be adapted to multiple types of materials.

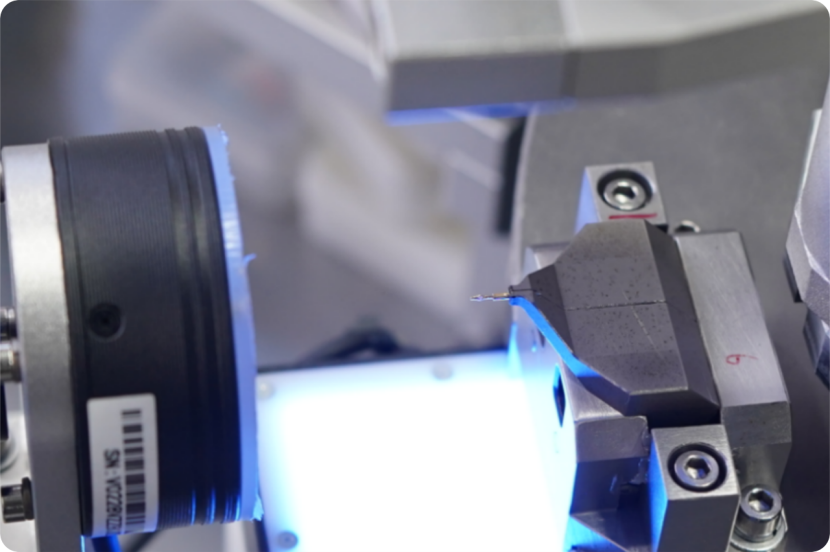

Multi-angle detection by CCD

CCD conducts multi-angle inspections on the crimping depth, direction, concentricity and size of the product, and accurately distinguishes between qualified products and defective ones.

PRODUCT PARAMETERS