Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

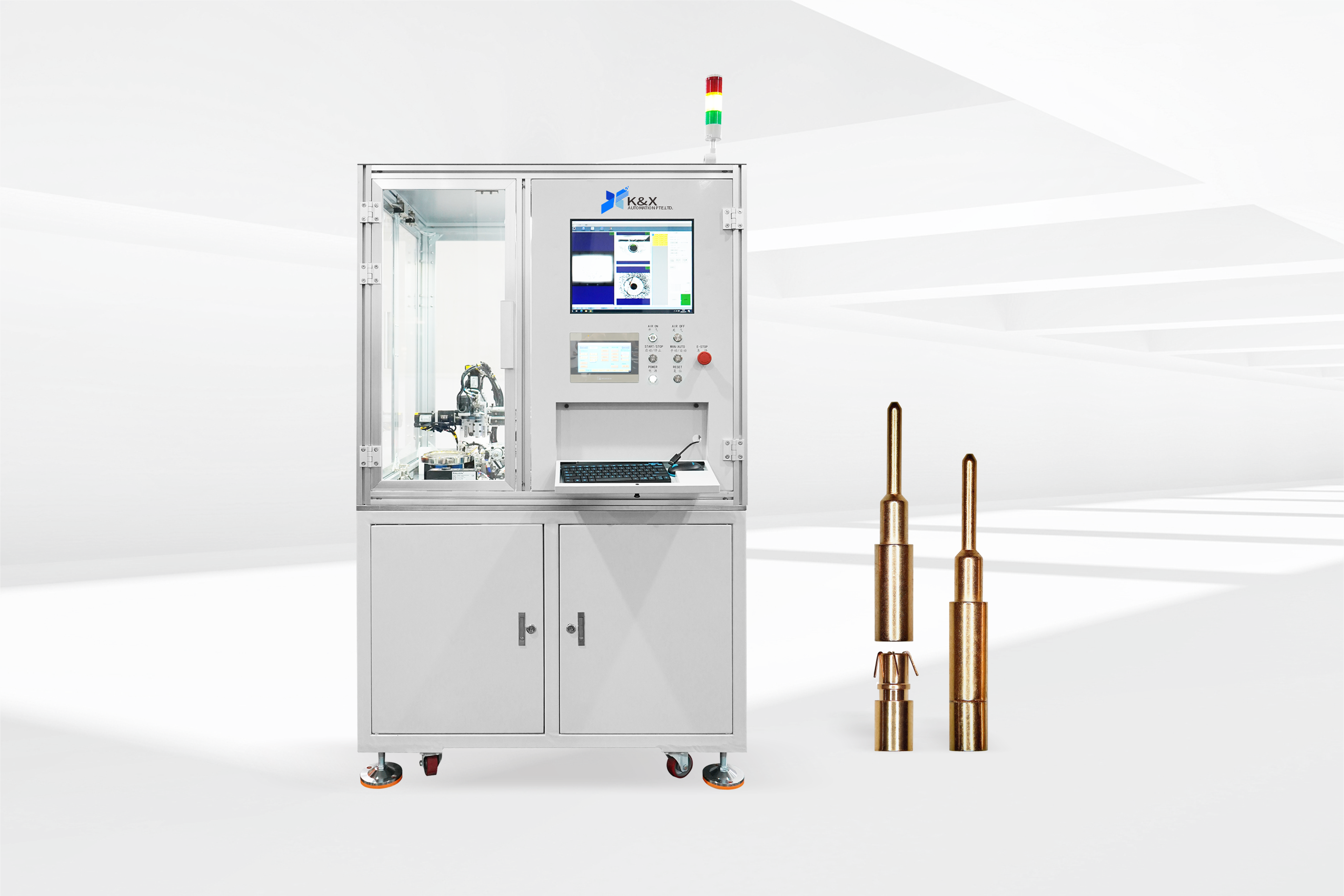

Hyperboloid Contact Crimping Machine

CORE TECHNOLOGY

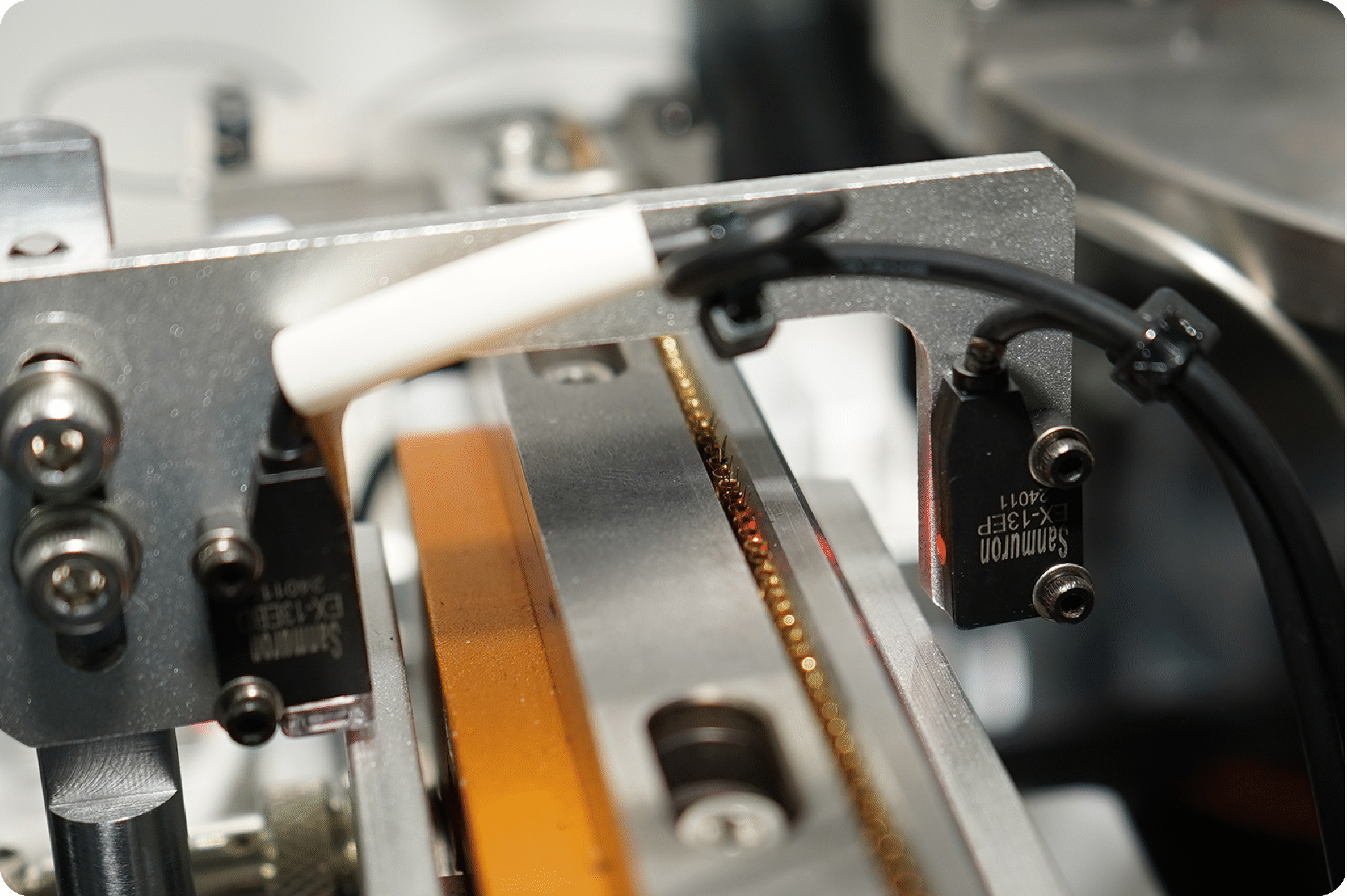

Optical fiber induction direct – vibration feeding

The front – sleeve vibrating plate directly vibrates for feeding. The optical fiber senses the presence or absence of products and stops feeding when full, ensuring precision and efficiency and avoiding material waste.

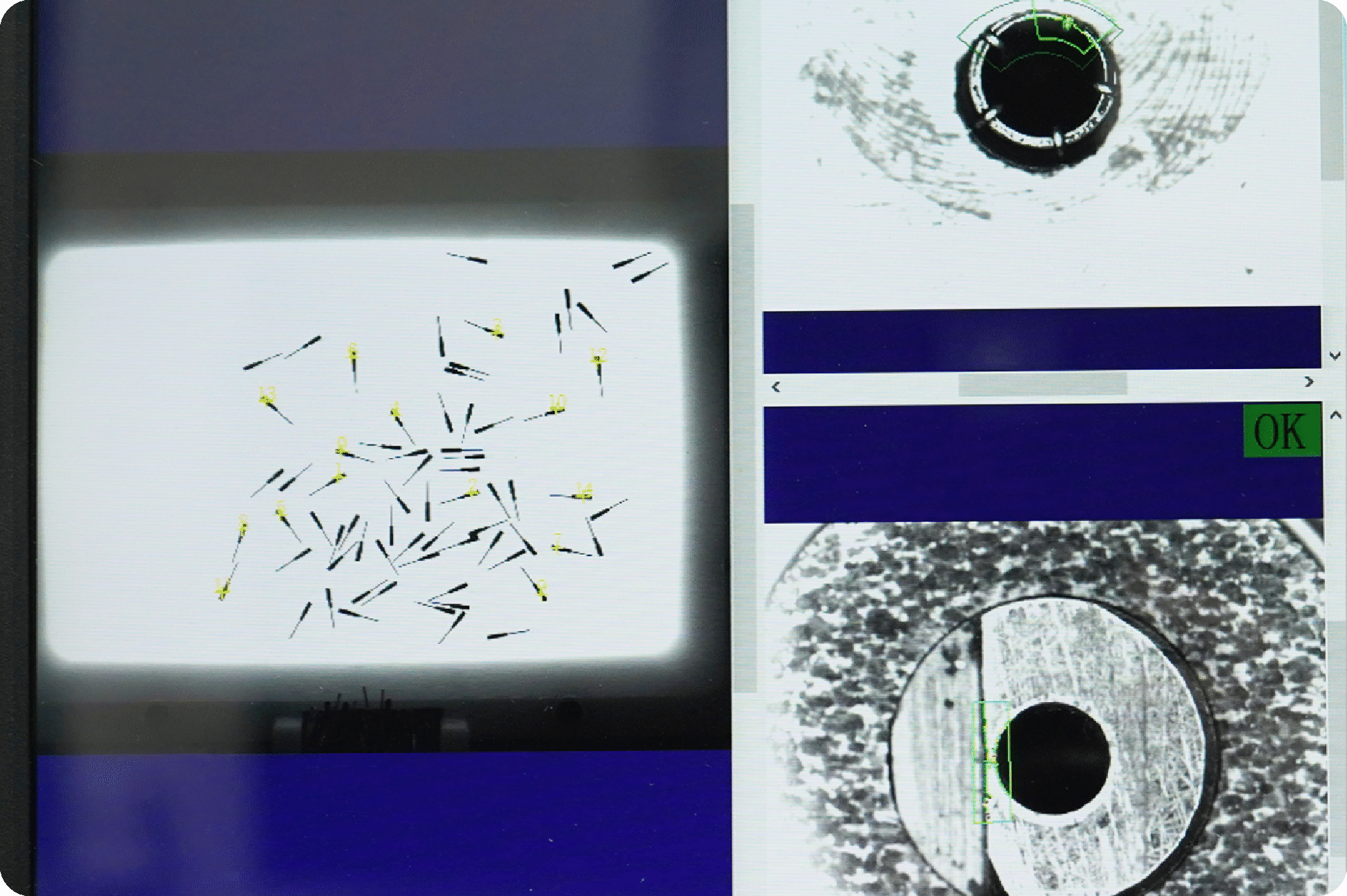

CCD vision recognition

Accurately identify whether the front – sleeve wire is broken and precisely determine the angle and direction of the front – sleeve and the mandrel. Automatically select the direction and insert the mandrel, with high precision and consistency.

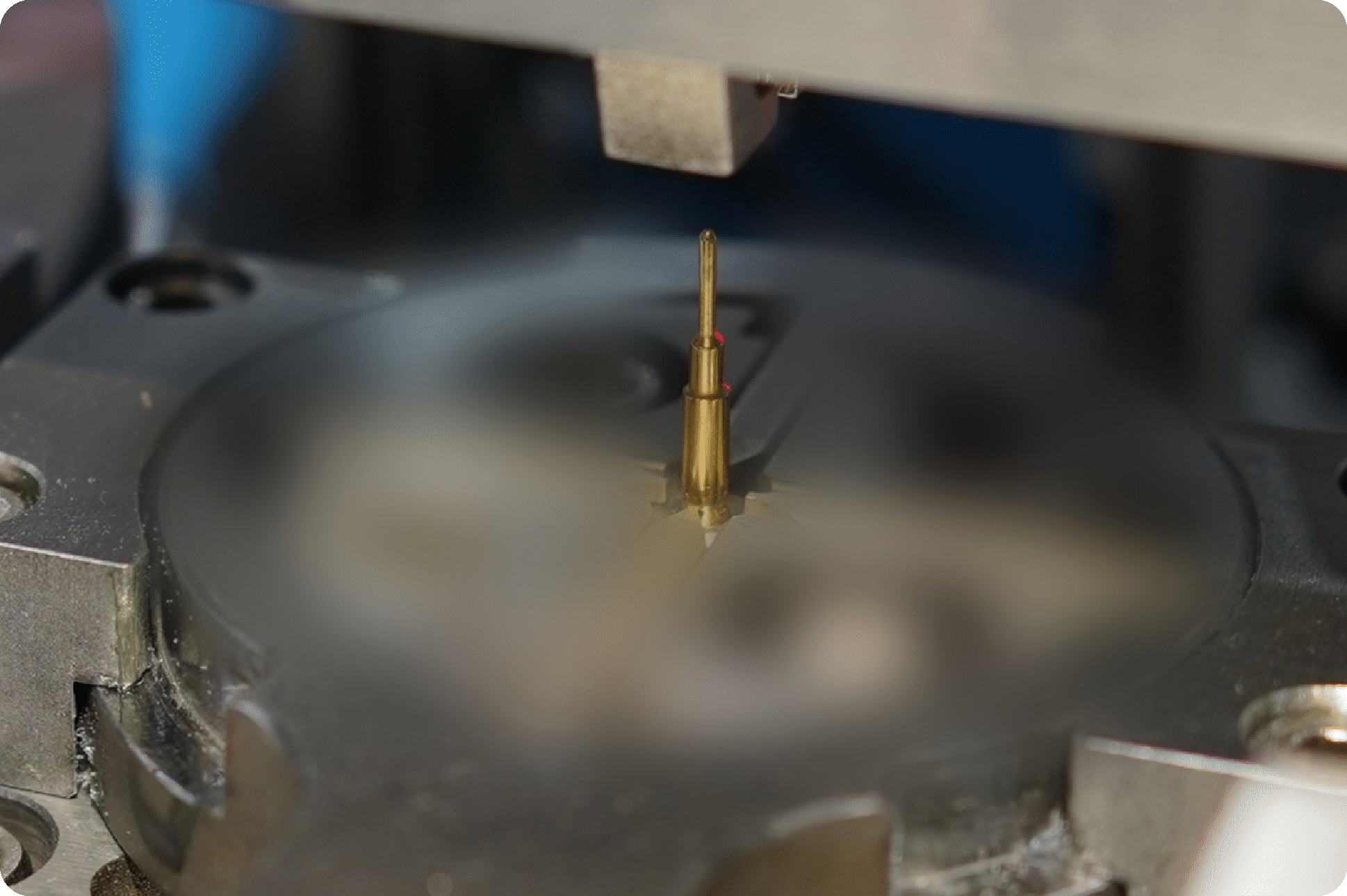

High – precision mandrel automatic wire – turning

The processing precision of the mandrel is as high as 0.005, stably supporting the wire – turning operation with zero – error precise positioning. Precisely control the angle, position, and force, ensuring uniform wire – turning angles. The mandrel mirror – surface polishing treatment prevents wire – breaking and scratching.

Precise four-point crimping

High – precision fixtures ensure the position accuracy of the locked bush. The fixtures rotate stably, and four – point crimping is carried out by servo motors. With few but precise fixtures, accurate product crimping is ensured.

PRODUCT PARAMETERS