Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

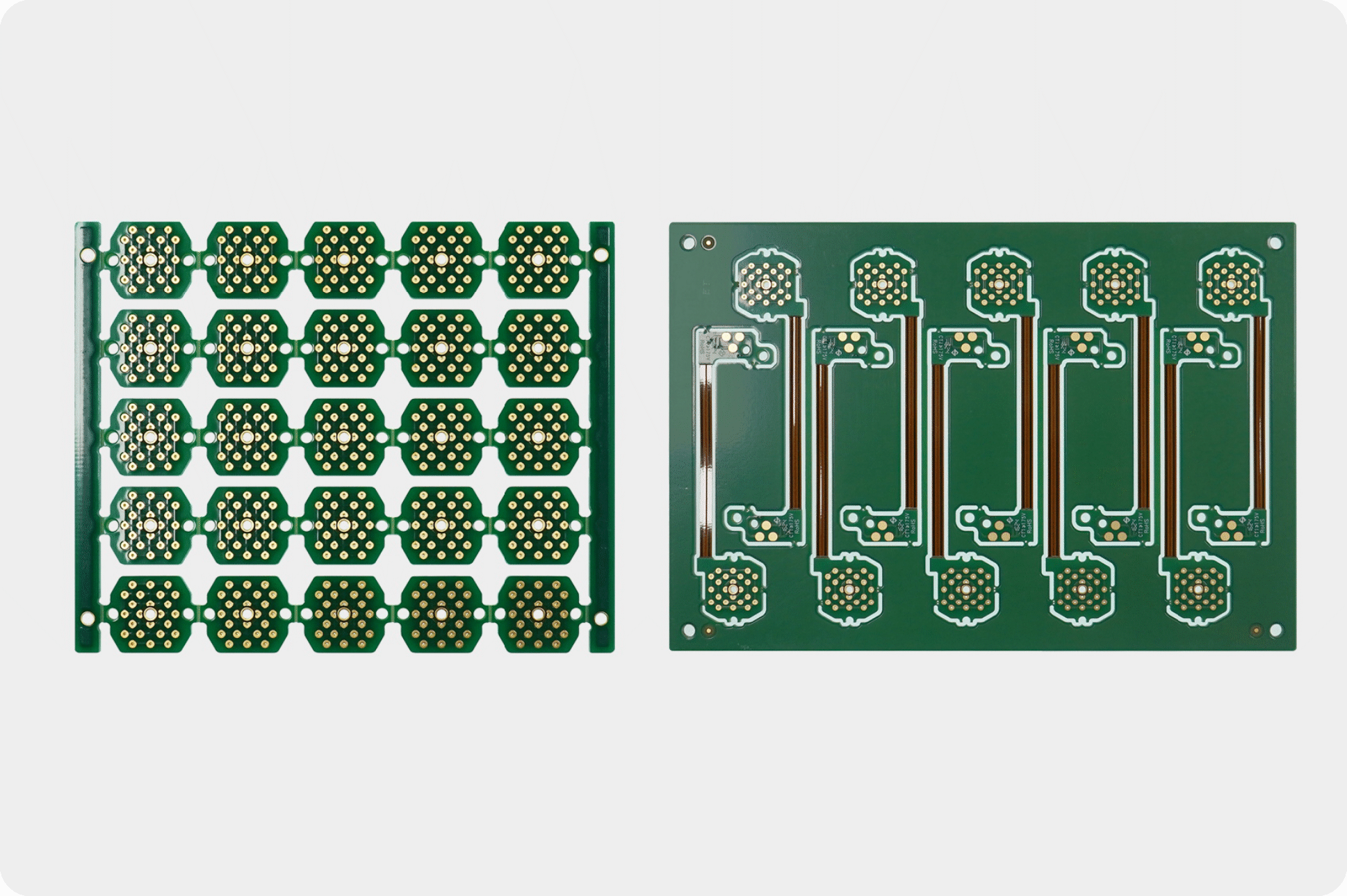

Automatic Pin Insertion Machine

CORE TECHNOLOGY

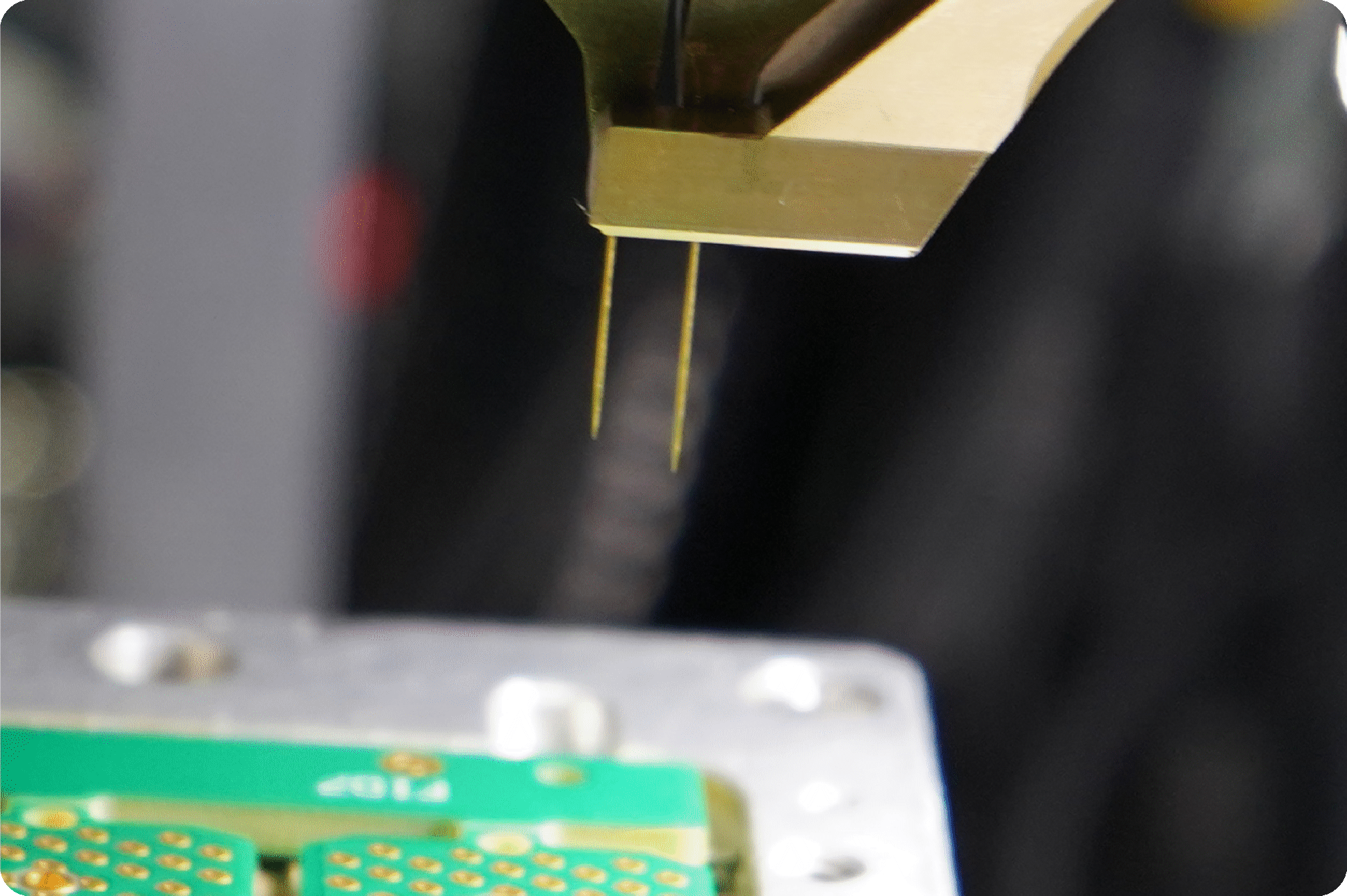

CCD – Positioned Flexible Loading

Materials are loaded onto a flexible vibrating plate, and a CCD camera combined with a four – axis robot accurately locates and grabs, capable of grabbing two materials at a time.

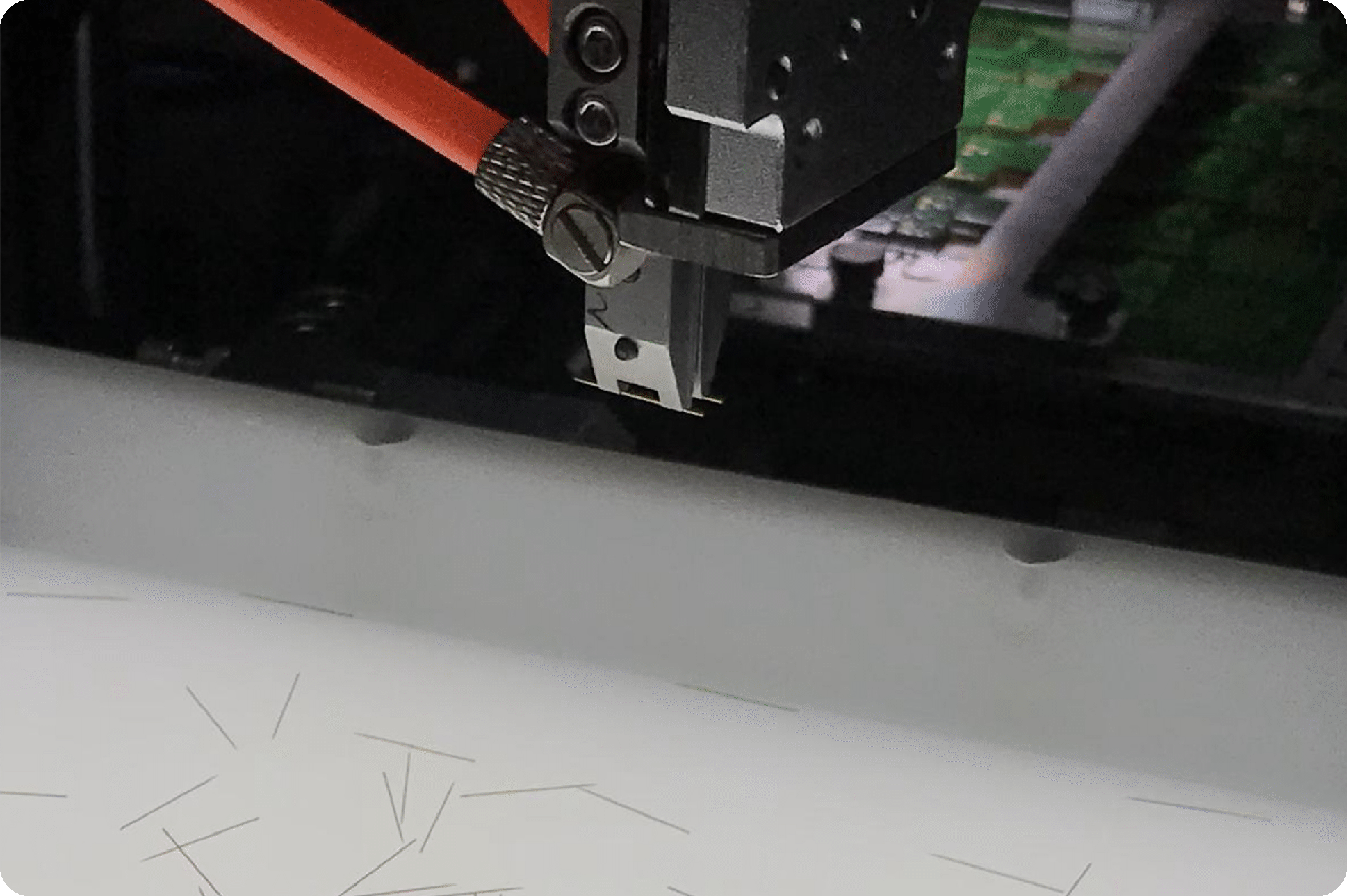

Efficient and Precise Pin Insertion

The pin insertion platform uses servo – controlled slide rails and lead screws, allowing flexible movement to corresponding pin insertion points with an error of no more than 0.1mm. It can complete 30 pin insertions per minute.

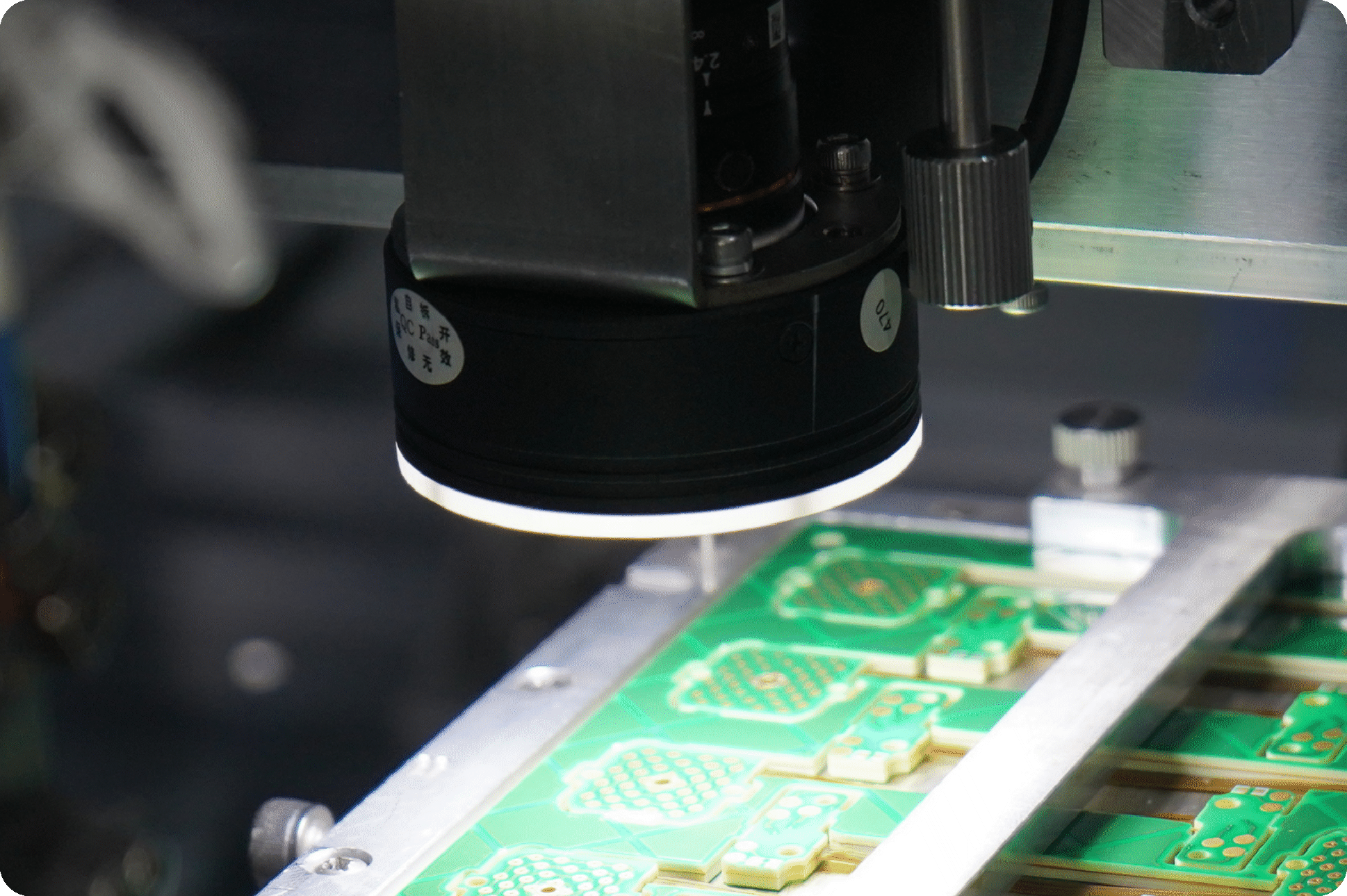

CCD Vision Inspection

The CCD monitors the movement to check for any missing pins on each small PCB board, improving product quality.

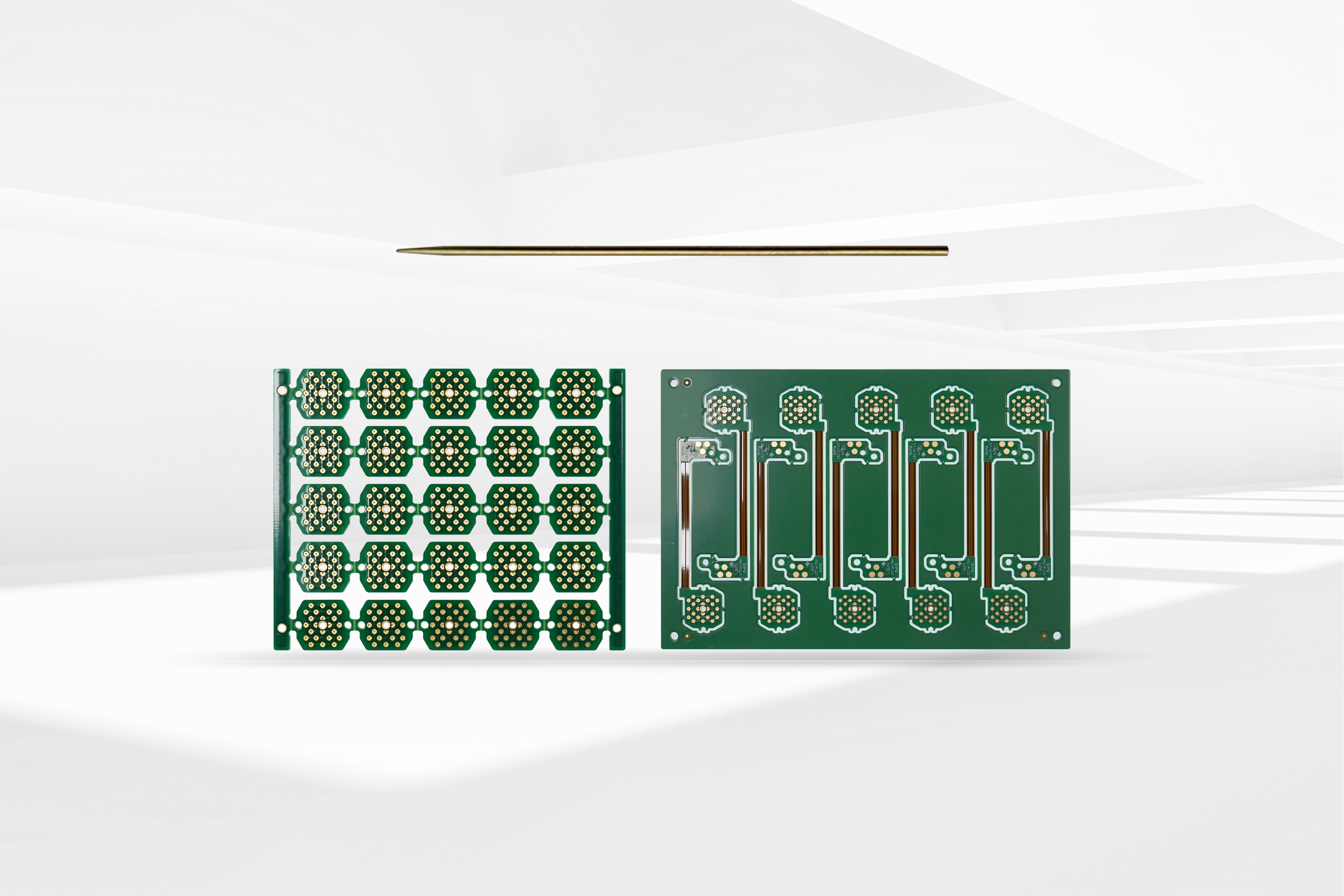

Multi – specification Adaptability

It can be applied to products of different types and sizes. By replacing corresponding fixtures and adjusting equipment parameters, pin insertion production of different products can be quickly achieved.

RODUCT PARAMETERS