Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

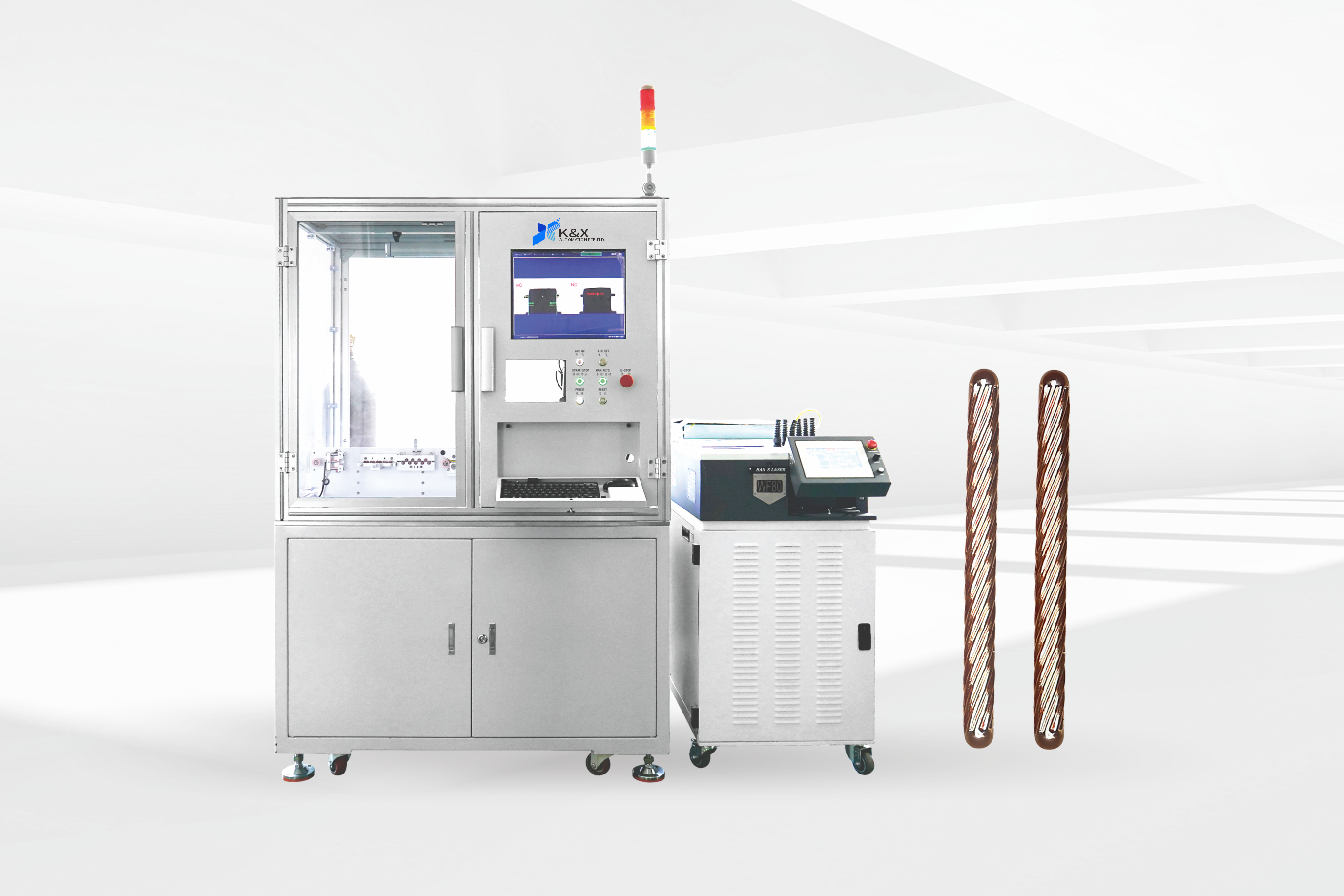

Twist Pin Cutting and Welding Machine

CORE TECHNOLOGY

Magnetic Damping Wire Reel Loading

The magnetic damping tension controller controls the pay – out tension of the wire reel, eliminates misaligned stress, and ensures the straightness of the twist pin wire.

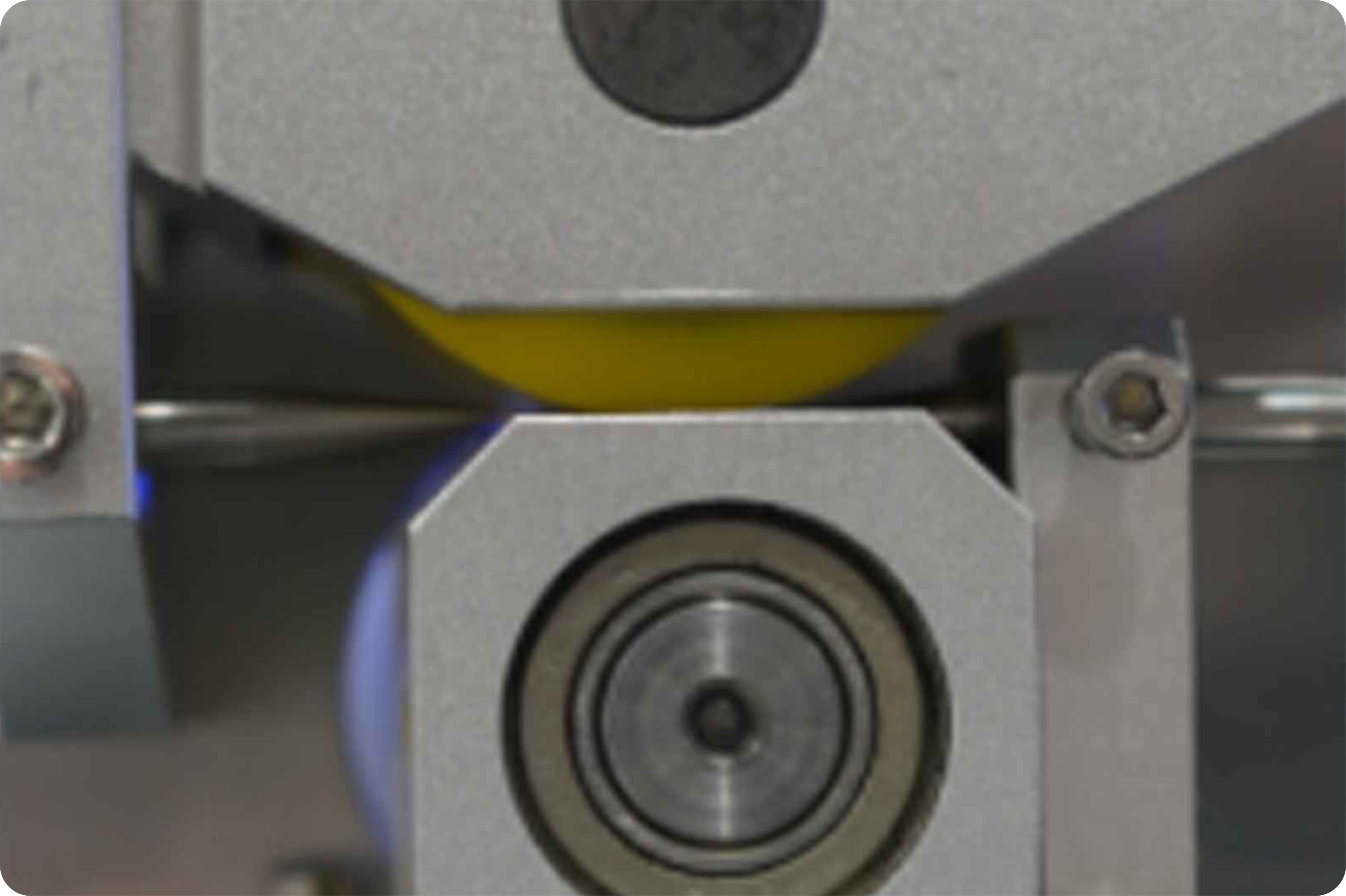

Precise Control of Incoming Wire Length

The pressing wheels are equipped with guide holes at both ends to ensure the straightness of the wire, and a servo drives the roller to feed the wire.

High – precision Cutting

The ejector pin ensures the consistency of the pin length, and pressing the tangents at both ends ensures a smooth cutting surface without wire scattering.

Precise Laser Welding

Laser welding is performed at both ends, resulting in firm and stable welding spots that are uniform in size, have a smooth and round appearance without deviation, and the use of inert gas makes the welding spots smooth and flat.

RODUCT PARAMETERS