Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

Automatic Side Brush Assembly for Sweeping Robots Machine

Short Description:

This equipment is applicable to the fully automatic assembly of side brush accessories for sweeping robots. It adopts a manual motor installation by workers and an automatic feeding system with a vibrating disk. The machine can complete processes such as automatic assembly of the bottom shell, shaft and gear, automatic screw locking, oiling and detection. Through the transmission fixtures for conveying, assembling and clamping products, it realizes the functions of fully automatic feeding assembly and finished product blanking.

CORE TECHNOLOGY

Fault and safety alarm system

It has functions such as abnormal alarm and information indication guidance, incoming material detection direction, and material shortage reminder.

The precision vibrating plate automatically loads and unloads materials

It has a high degree of automation, realizing automatic loading of the vibrating plate and automatic unloading of finished products, greatly increasing work efficiency. Compared with manual material placement, it saves time and effort.

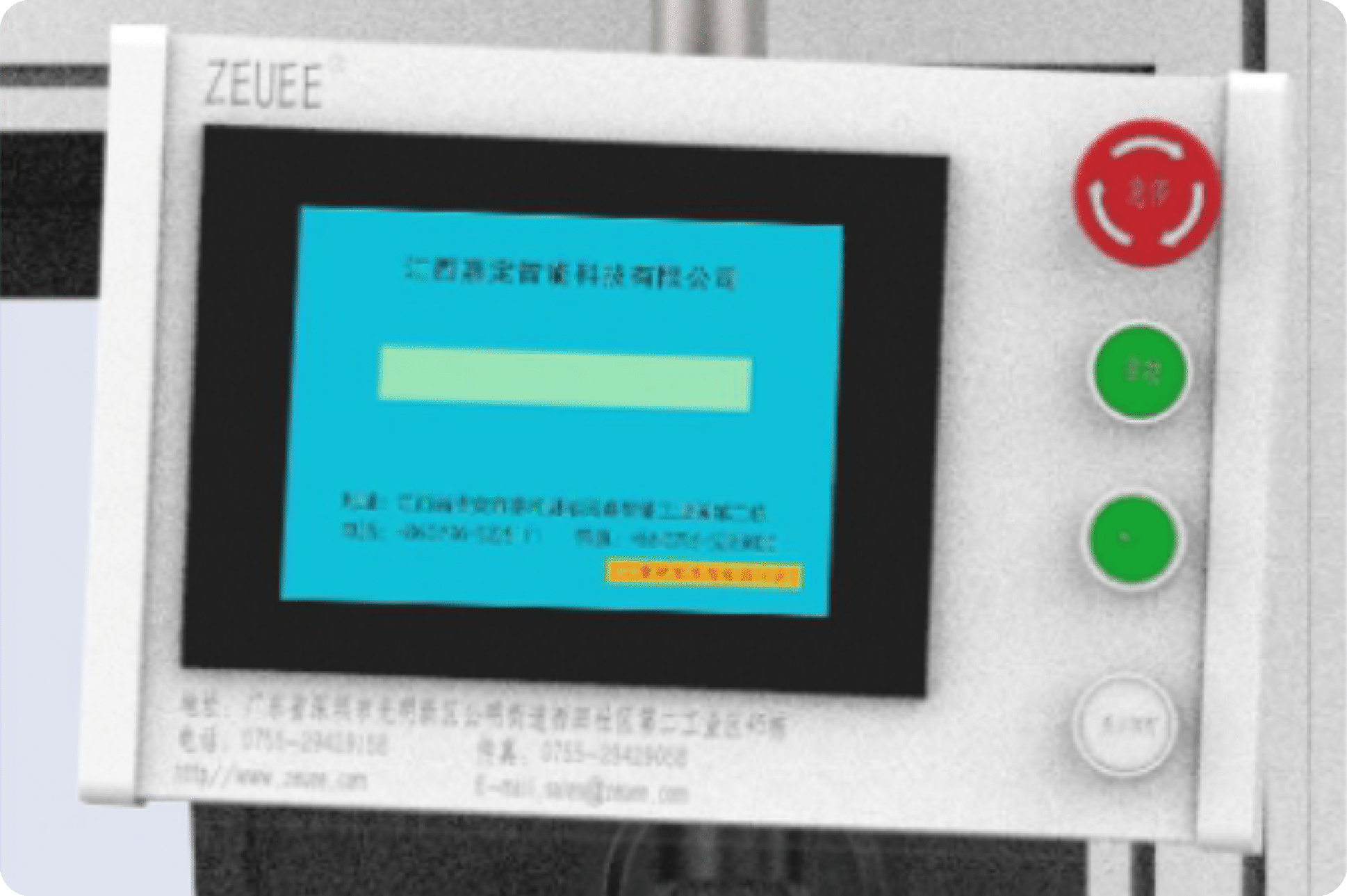

Touch – controlled human – machine interface

The touch – controlled human – machine interface has adjustable intelligent parameters, preset quantity production, counting function, historical alarm recording function, etc.

PPU robotic hand for automatic gripping

It has high repeatability precision, fast and stable operation. It can automatically transfer, feed, and remove components in a confined space, perfectly solving the problem of manual feeding.

RODUCT PARAMETERS

Dimensions:10000mm*3100mm*2000mm

Productivity:8-12PCS/MIN

Power:8KW

Air pressure / Voltage:0.4 MPa-0.6 MPa/220/380 V 50 HZ

Leave Your Message