Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

Rotary Buckle Automatic Positioning Packaging Inspection Machine

CORE TECHNOLOGY

Rubber – coated gripper

It uses pneumatic rubber – coated grippers to firmly grasp materials and accurately deliver them to the designated positions, effectively preventing materials from being scratched.

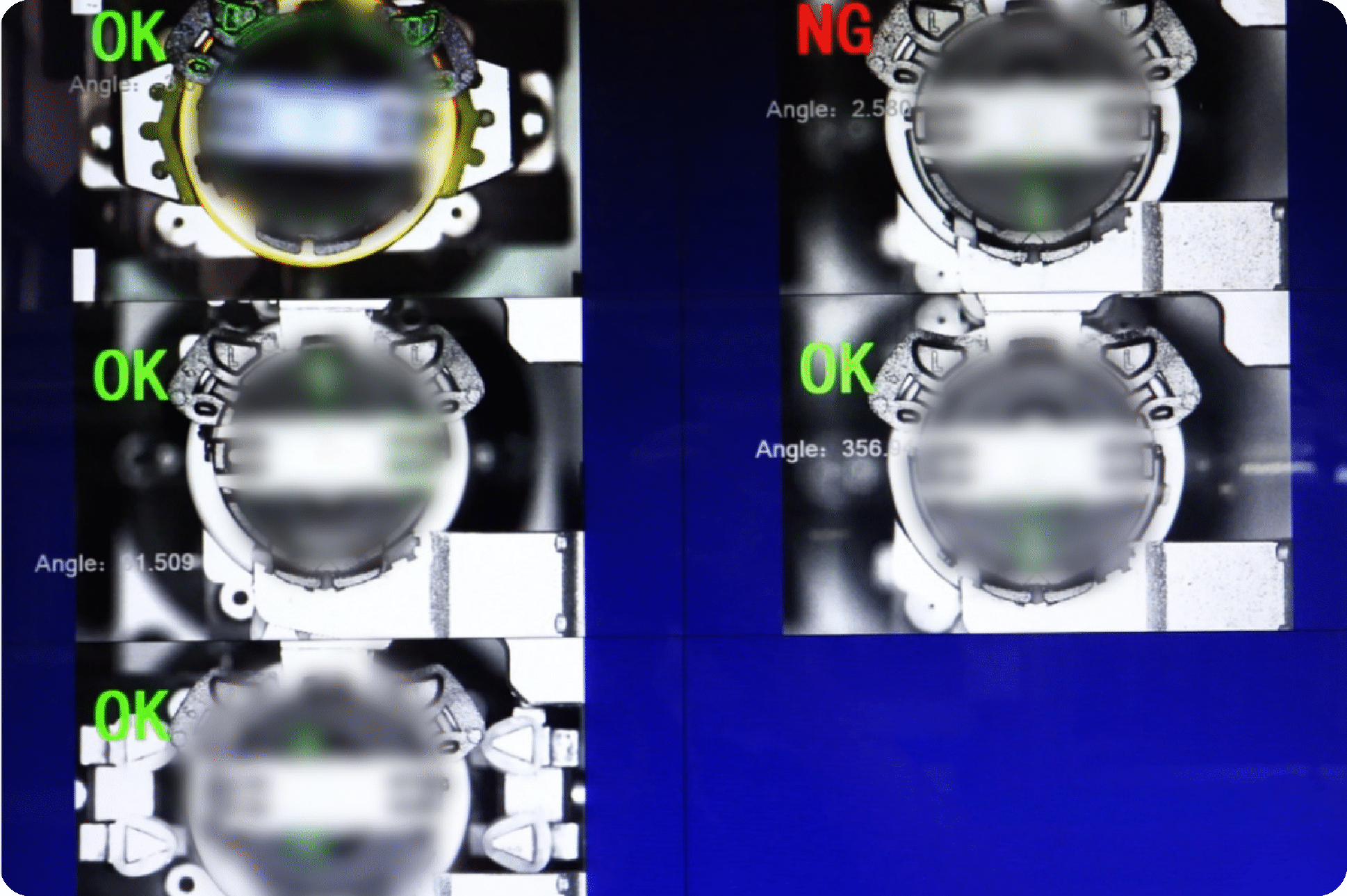

CCD Vision Monitoring

Using CCD color cameras to accurately identify the direction of material arrows and letter positions, secondary inspection of arrow positions to improve reliability, automatic correction of material direction to ensure that materials are in the correct position during inspection and packaging.

Intelligent Sorting

Based on test results, automatically sort qualified products from unqualified ones, effectively preventing unqualified products from entering subsequent packaging processes, ensuring the precision and efficiency of product quality control.

Automatic film – covering, tray – arranging, and blanking

High – precision pneumatic claws combined with probes for precise detection and grasping of materials; positioning film – covering combined with negative – pressure gauges for precise isolation and protection of materials. Achieve automatic tray – arranging, which can flexibly adapt to different materials, improving packaging quality and efficiency.