Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

Copper Parts Automatic Assembly Machine

CORE TECHNOLOGY

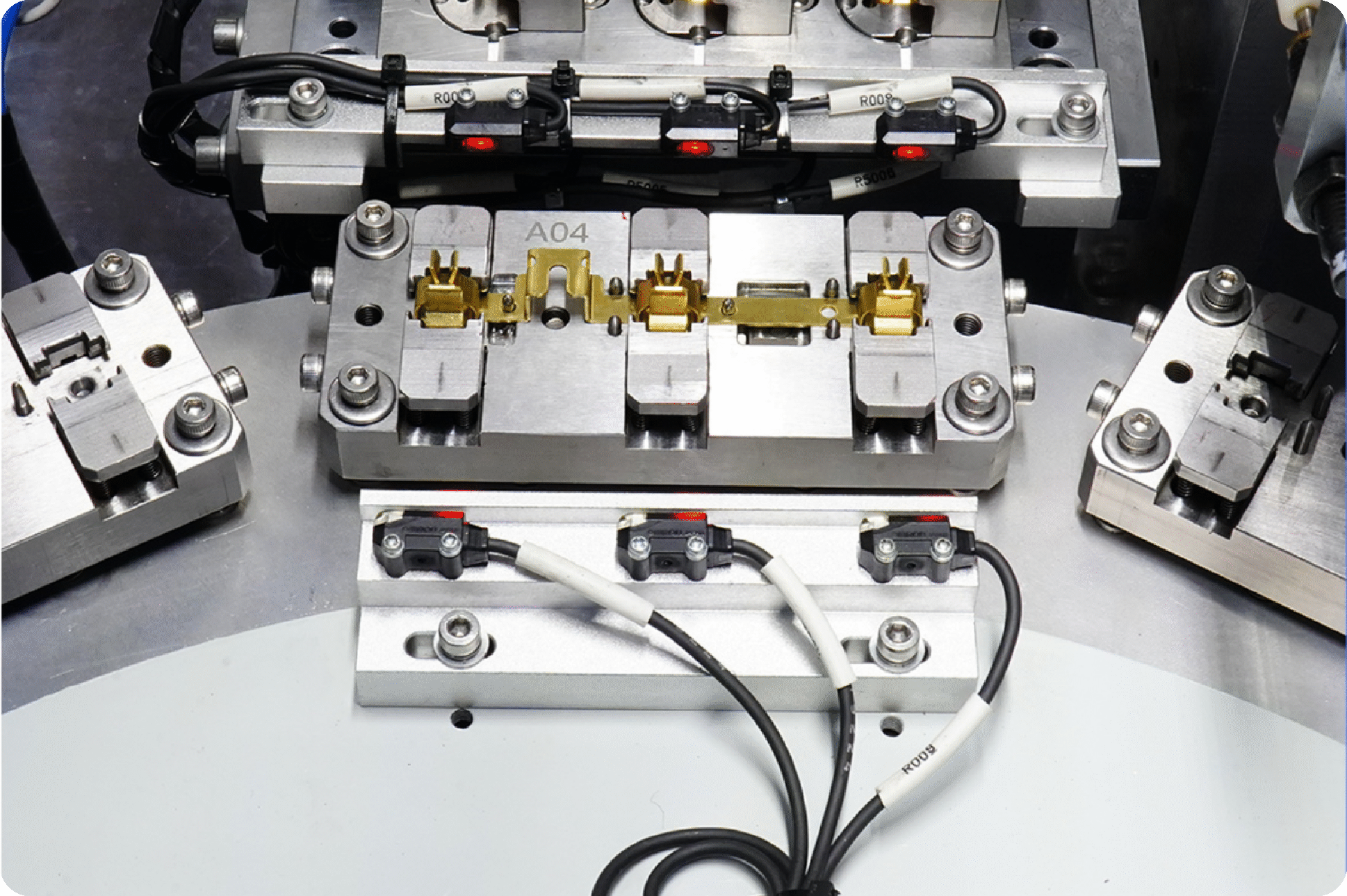

Disc-type structure

It features a disc-type structure with an advanced layout. The assembly process is highly efficient and smooth. Jigs can be switched at any time, and there’s no need for manual intervention when changing models, which fully demonstrates high efficiency and intelligence, helping you stay ahead all the way.

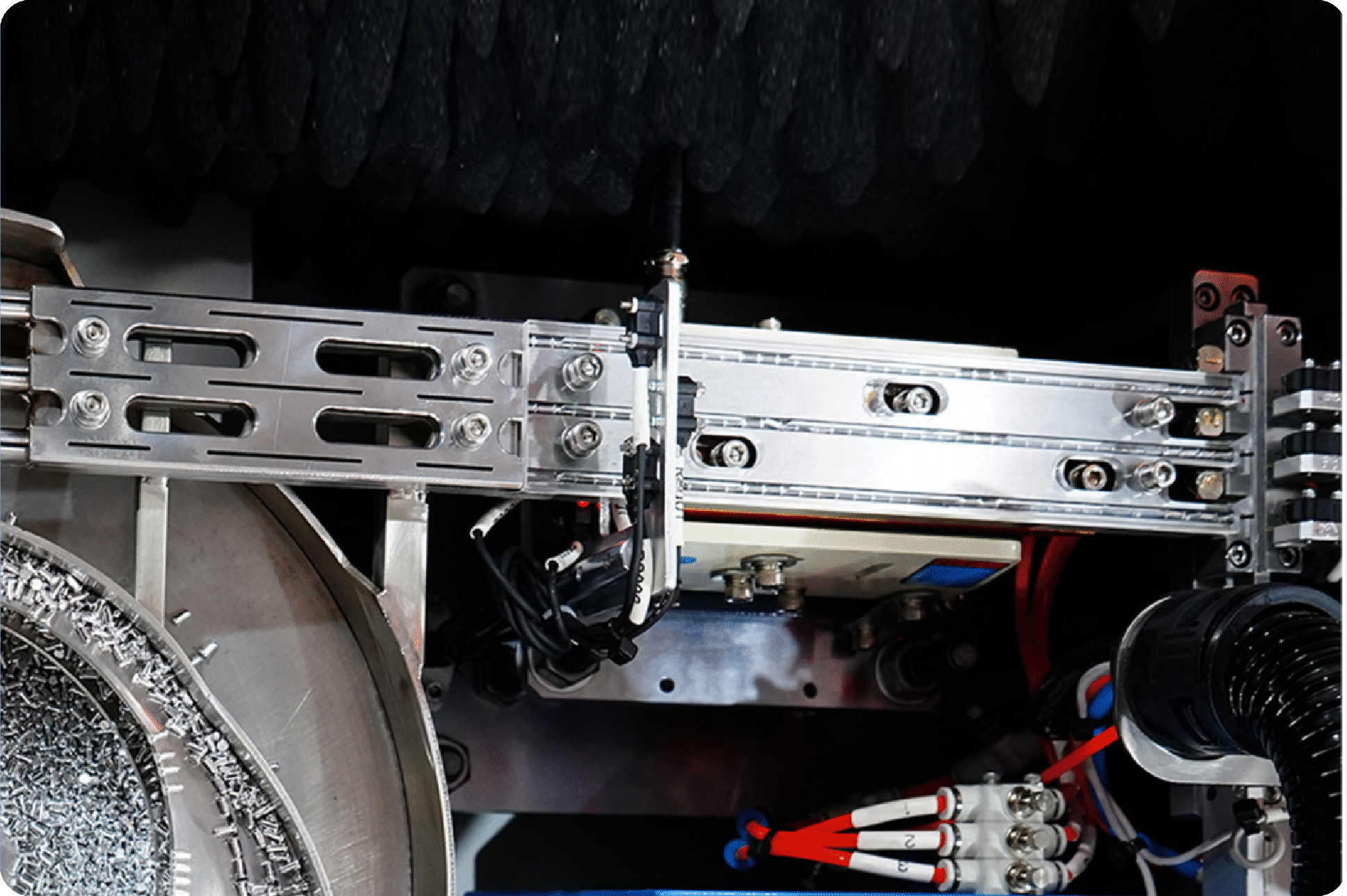

Efficient feeding of rivets

The rivets are fed precisely by the vibrating plate through direct vibration. The short material channel prevents materials from getting stuck. The vibrating plate discharges materials horizontally with the heads facing forward, which increases the contact surface and improves stability, thus safeguarding the production process.

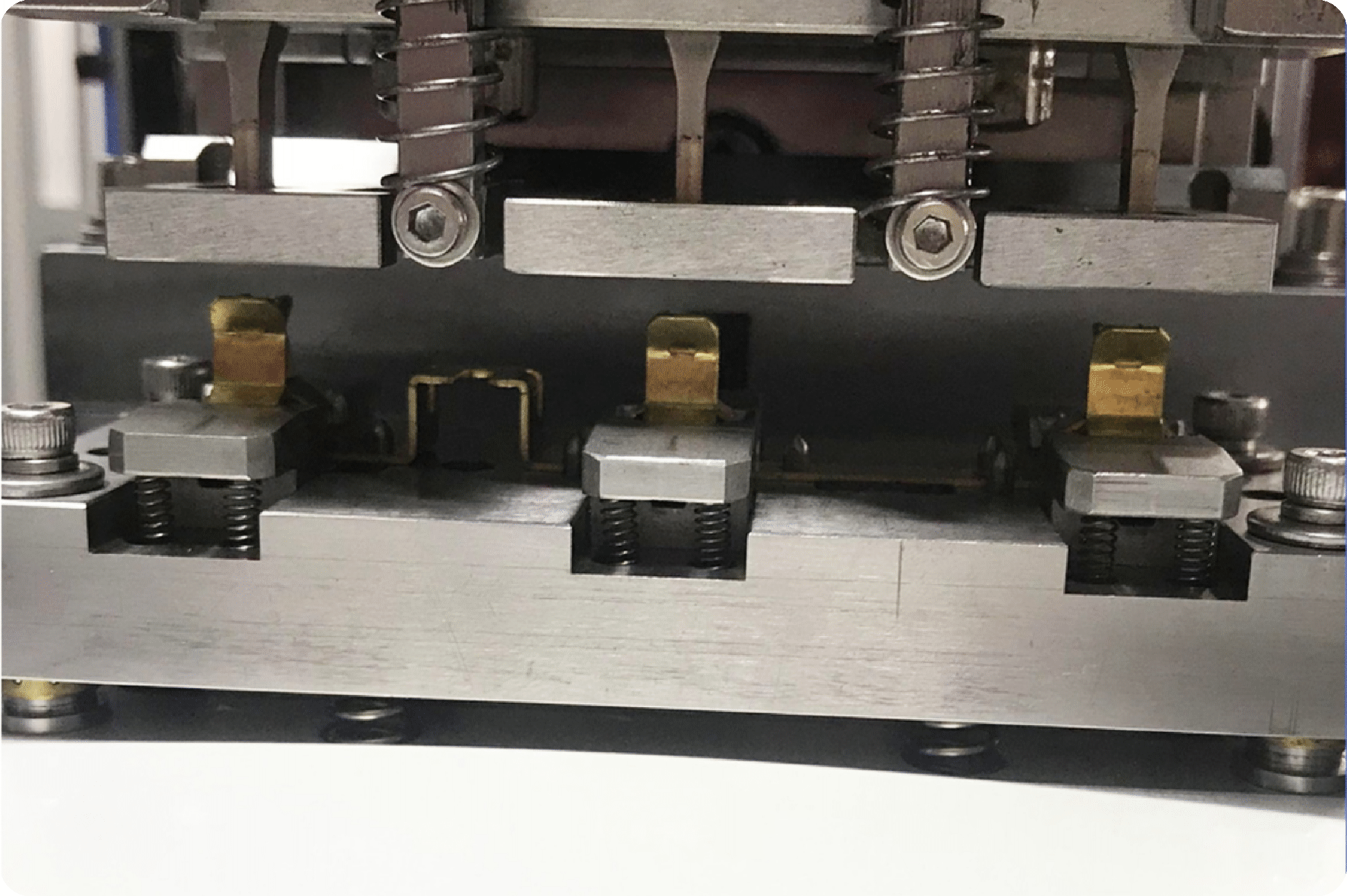

Precise positioning and riveting

Three copper parts are riveted simultaneously, with a tight connection, achieving outstanding assembly quality for copper parts.

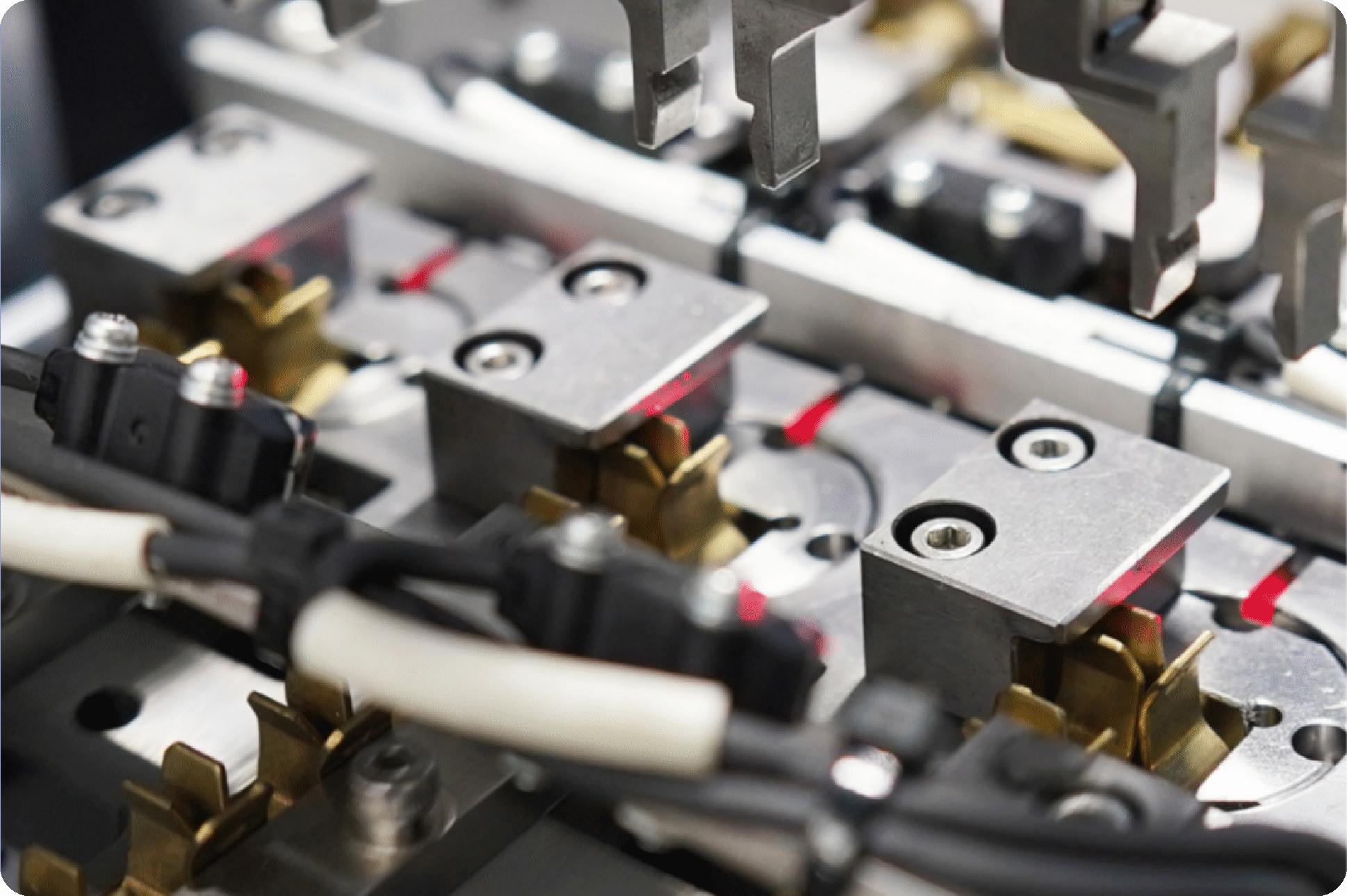

Online optical fiber monitoring

The equipment is equipped with optical fiber material arrival detection and material shortage detection, and it can automatically alarm in case of abnormalities.

RODUCT PARAMETERS