Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

DC Line Fully – Automated Production Line

CORE TECHNOLOGY

Automatic Wire Straightening

The pay – off rack precisely releases the wire, and the straightening device efficiently eliminates the bending and twisting of the wire, effectively ensuring the precision of subsequent processing.

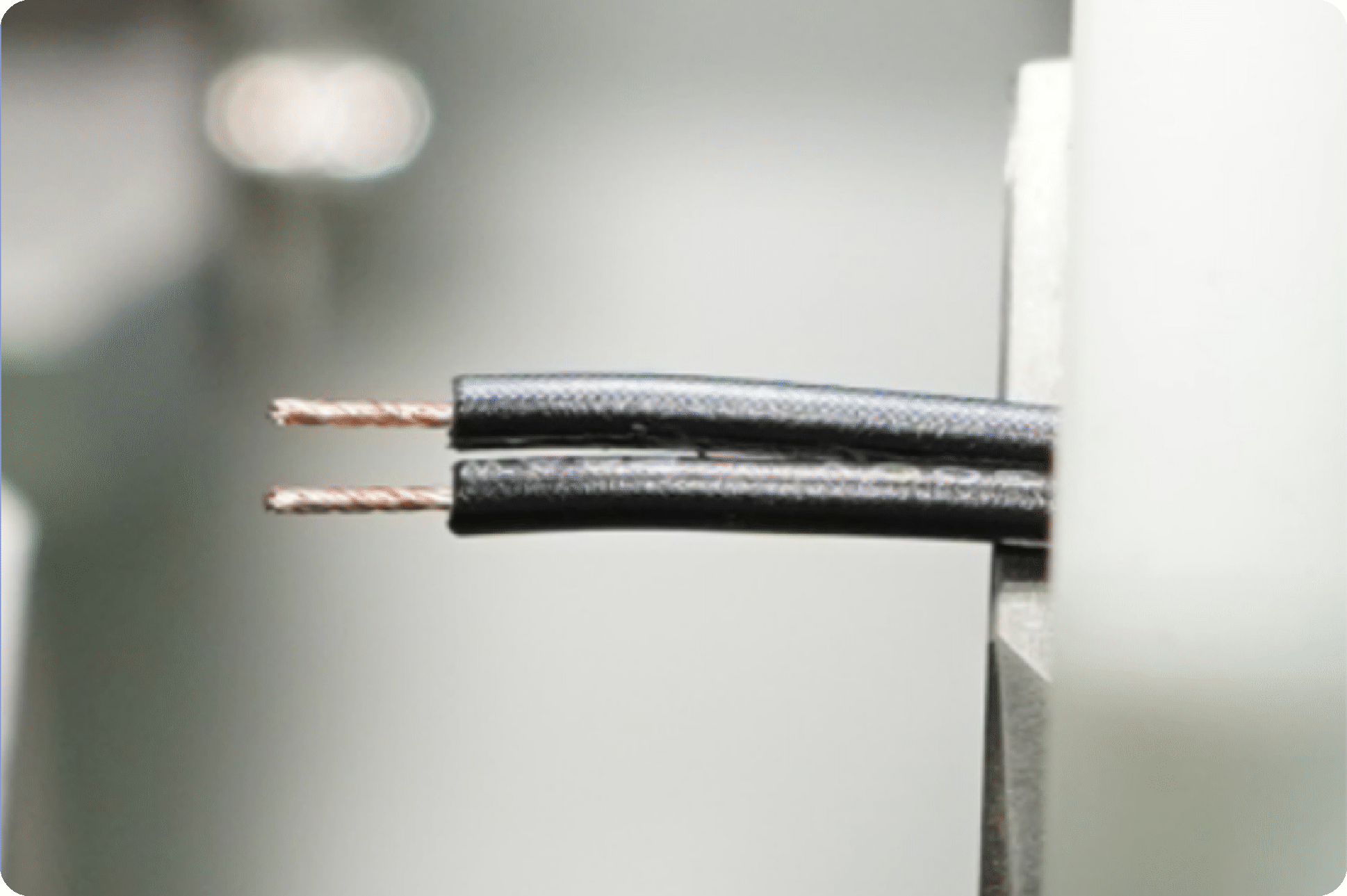

High – efficiency Stripping and Twisting

High – precision stripping tools accurately cut the insulation layer of the core wire, ensuring the accuracy of stripping depth and length. The twisting mechanism quickly and evenly twists the core wire and completes the stripping.

Waste Treatment

The mechanical hand automatically clamps and sends out the waste from the injection molding gate, and the waste is cleaned through the cleaning mechanism to achieve efficient waste treatment.

Automatic Wire Winding and Tying

The DC wires are automatically wound, with the winding being tight and neat. The high – efficiency wire – tying device can quickly complete the operation, ensuring that the tied wires are firm and do not come loose. There is no need for manual intervention, effectively improving production efficiency.

RODUCT PARAMETERS