Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

Plastic Brush Automatic Assembly Machine

Short Description:

It adopts the automatic assembly of sweeping robots parts, and can complete the processes of automatic assembly of the mandrel, sponge, rubber sheet, end cover, copper sleeve, top cover and detection by using of the plastic brush and the automatic feeding system of the vibrating disk. Products are conveyed, assembled and clamped through the transmission fixture to realize the functions of fully automatic feeding assembly and finished product blanking.

CORE TECHNOLOGY

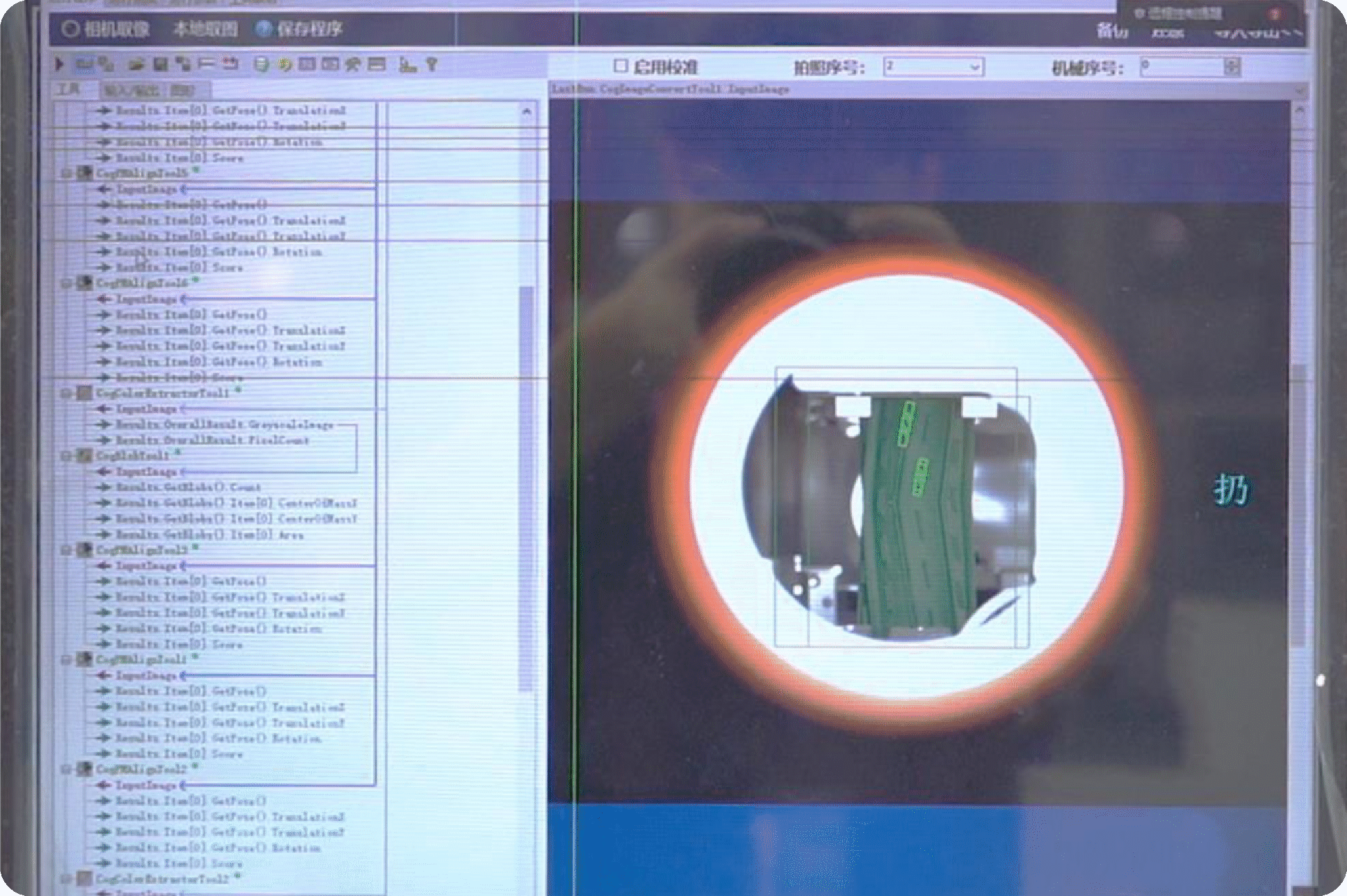

Automatic error correction

Abnormal error can be detected by CCD and automatic corrected to help improve products pass rate.

Data recording and analysis

Record and analyze the data during assembly and detection to improve production process and quality control better.

Multi-specification adaptation

It can adapt to the assembly requirements of various specifications and models of plastic brushes, and has strong versatility.

Visual operation

The operation interface is intuitive and easy to understand, facilitating worker to set parameters and monitor.

RODUCT PARAMETERS

Dimensions:12500mm*7000mm*2000mm

Productivity:16 – 18pcs/min

Power:10kw

Air pressure / Voltage:0.5–0.6Mpa/AC220V

Leave Your Message